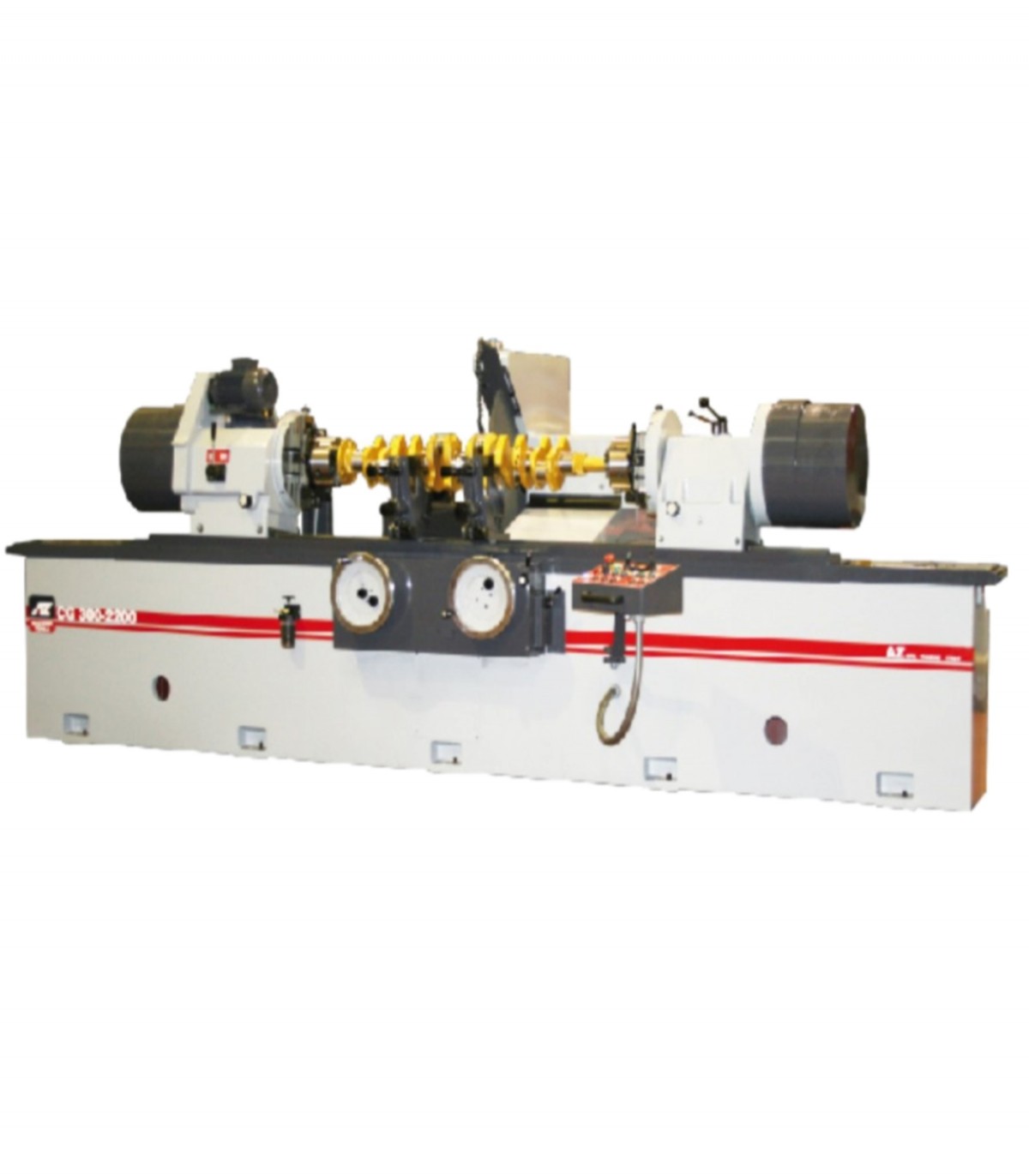

Four indexing locations on the head stock with the air operated index pins make it faster to dial in the crankshaft properly. Easily adjusted outboard counterweights never need to be supplemented by inboard weights. The CG300 are built very heavy with widely spaced ways to assure positive alignment of the wheelhead to the table. Moreover, the controls are easier to use. Precision Incremental In-Feed Lever is much easier to use than a handwheel to achieve the precise desired journal size. The superior accuracy of this machine allows double plunge grinding precisely to the same size leaving no lap line. CG300 provides longer machine life, longer grinding wheel life and greater safety for the operator and machine.

The crankshaft grinding machines model CG have peculiar characteristics that permit easy and quick set-up and operating of the crankshaft. These qualities have been reached after a particular design and realisation of the headstock and the relative tailstock.

- The precise connection between the prismatic and flat guides of the basement and the table permit high stability and a perfect perpendicularity with the wheelhead

- Big base to permit the working of big crankshaft without extending the table beyond the base for more than 10% of its length

- Group of leveling points for a better leveling and for the corrections of possible distortions of the machine

Data sheet

- Model

- CG300

- Height of centers

- 300 mm

- Max distance between centers

- 2200 mm

- Swing over table

- 600 mm

- Grinding wheel diameter

- 815 mm